Automotive design is more than just visual appeal; it is a cornerstone of performance, safety, and efficiency. In today’s automotive landscape, where sustainability and fuel economy are top priorities, design has a direct influence on a vehicle’s aerodynamics and overall fuel consumption. Engineers and designers collaborate closely to create vehicles that slice through air more efficiently, reducing resistance and improving performance.

The evolution of automotive design is being driven by technological advancements, environmental regulations, and customer demand for better-performing, fuel-efficient vehicles. With each design iteration, automakers are challenged to maintain aesthetic appeal while simultaneously enhancing aerodynamic properties. This delicate balance is shaping the future of mobility and influencing everything from compact cars to high-performance electric vehicles.

Understanding the Basics: What Is Aerodynamics in Automotive Design?

Aerodynamics in automotive design refers to how air flows around a vehicle as it moves. This flow directly affects the amount of drag—a force that opposes motion—encountered by the vehicle. The more aerodynamic a car is, the less energy it requires to overcome drag, leading to improved fuel efficiency and better high-speed stability.

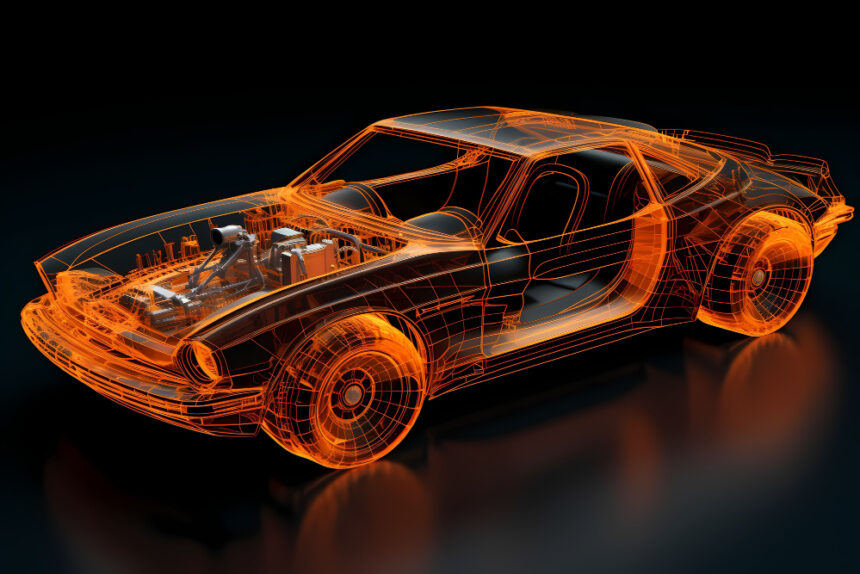

The principles of aerodynamics rely on reducing air resistance and managing airflow in a way that minimizes turbulence. Automotive designers use wind tunnels, computational fluid dynamics (CFD), and real-world testing to evaluate how air moves around a vehicle. Design elements like the slope of the roof, the shape of the front fascia, and the contour of the underbody all contribute to a car’s aerodynamic efficiency.

The History of Automotive Design and Its Evolution Toward Aerodynamic Efficiency

The journey of automotive design has seen dramatic shifts since the first motor vehicles. In the early 20th century, aesthetics dominated design, with little concern for fuel efficiency. Cars were boxy, tall, and not optimized for aerodynamic performance. However, as the oil crisis of the 1970s emerged and environmental consciousness increased, manufacturers began emphasizing fuel economy, and aerodynamic design became a critical factor.

By the 1980s, vehicles began featuring more sloped front ends, curved windshields, and flush surfaces. Concepts like the drag coefficient (Cd) gained prominence, and automakers invested in refining vehicle shapes to reduce this number. Today, even minute changes in body design are calculated to enhance aerodynamic efficiency, with many modern sedans achieving drag coefficients below 0.30.

Key Elements of Automotive Design That Influence Aerodynamics

Several components of a vehicle’s design directly affect its aerodynamic performance. Among the most influential are

- Front Grille and Air Intake: These affect how air enters and exits the engine bay. Active grille shutters are now commonly used to optimize airflow dynamically.

- Roofline and Rear Slope: A gently sloping roofline and streamlined rear reduce vortex formation and lower drag.

- Underbody Panels: Flat, covered underbodies minimize airflow disruption beneath the car.

- Side Mirrors and Door Handles: These small features can create drag, and designers now incorporate slimmer, integrated components to reduce their impact.

- Wheel Arches and Spoilers: Properly designed wheel wells and spoilers can manage turbulent airflow and enhance vehicle stability.

Each of these elements must be carefully balanced to maintain both aerodynamic function and visual appeal, making automotive design a complex and multifaceted discipline.

The Drag Coefficient: Measuring Aerodynamic Efficiency

The drag coefficient (Cd) is a numerical representation of a vehicle’s aerodynamic resistance. It quantifies how efficiently a car can move through the air, and lower values indicate better aerodynamic performance. Most passenger cars today aim for a Cd between 0.25 and 0.30, with some advanced electric vehicles reaching as low as 0.20.

To calculate the drag force, the equation used is F_d = (1/2) * ρ * v^2 * A * Cd, where

- F_d is the drag force

- ρ is air density

- v is vehicle speed

- A is frontal area

- Cd is drag coefficient

Automotive design teams work to reduce the Cd while managing the trade-offs involved in aesthetics, manufacturing feasibility, and occupant comfort. Aerodynamic testing in wind tunnels and CFD simulations are essential tools in this optimization process.

How Vehicle Body Shapes Affect Aerodynamics and Fuel Efficiency

The shape of a vehicle plays a significant role in determining how air flows around it. Streamlined shapes, like those of sports cars and sedans, reduce drag more effectively than boxy forms typically found in SUVs and trucks.

For example, teardrop-shaped vehicles are considered the ideal form in aerodynamics due to their smooth, continuous lines that allow air to flow with minimal disruption. Hatchbacks and coupes often adopt variations of this shape to balance performance and practicality. In contrast, larger vehicles with flat fronts and square rears experience more drag, requiring additional design innovations to improve efficiency.

Manufacturers use design features such as roof spoilers, rear diffusers, and side skirts to channel airflow more efficiently, compensating for less aerodynamic shapes. Automotive design must therefore integrate aerodynamics without compromising interior space and utility.

Materials and Technologies Supporting Aerodynamic Automotive Design

Modern automotive design increasingly leverages lightweight materials and smart technologies to support aerodynamic goals. Lightweight materials such as aluminum, carbon fiber, and high-strength steel allow designers to create sleeker body shapes without compromising structural integrity.

Active aerodynamic systems have also become more prevalent. These include features like adaptive spoilers, variable air dams, and self-adjusting suspension systems that optimize the vehicle’s posture relative to the road. These technologies respond dynamically to speed and driving conditions, reducing drag when cruising and increasing downforce when cornering.

Additionally, advancements in manufacturing processes, such as precision stamping and robotic assembly, allow for more complex and accurate body panel designs. This level of precision enhances both visual appeal and aerodynamic performance.

Electric Vehicles and the New Frontier in Aerodynamic Automotive Design

Electric vehicles (EVs) present unique challenges and opportunities for automotive design. Since EVs do not require large front grilles for engine cooling, designers have more flexibility to create smoother front profiles. This results in lower drag coefficients and improved range—a crucial metric for electric mobility.

Automakers like Tesla, Lucid Motors, and Mercedes-Benz have set new benchmarks for aerodynamic design in EVs. The Tesla Model S and Lucid Air, for example, feature drag coefficients as low as 0.208 and 0.21, respectively, thanks to optimized body shapes, recessed door handles, and fully enclosed underbodies.

As the automotive industry shifts toward electrification, aerodynamic design will continue to evolve, pushing the limits of efficiency and redefining vehicle aesthetics. Future EVs will likely feature even more integrated aerodynamic elements, powered by real-time AI-driven optimization systems.

Real-World Examples: Aerodynamically Optimized Vehicles

Several production vehicles have made headlines for their aerodynamic excellence. Here are a few notable examples:

- Mercedes-Benz EQS: With a drag coefficient of 0.20, it is one of the most aerodynamically efficient production cars ever made.

- Tesla Model 3: Features a smooth underbody, minimal grille, and low-profile design, contributing to its impressive Cd of 0.23.

- Toyota Prius: A pioneer in hybrid efficiency, the Prius uses a wedge-shaped body and carefully sculpted surfaces to maximize fuel economy.

- Audi A7 Sportback: Combines luxury with aerodynamic functionality, featuring a liftback design that reduces air turbulence.

Each of these vehicles demonstrates how automotive design decisions directly influence aerodynamic performance and, by extension, fuel efficiency and environmental impact.

The Future of Automotive Design: Balancing Innovation and Efficiency

The future of automotive design lies at the intersection of aesthetics, efficiency, and sustainability. As regulations tighten and consumer expectations evolve, designers are under increased pressure to deliver vehicles that are not only beautiful but also incredibly efficient.

Emerging trends include bio-inspired designs that mimic nature’s most aerodynamic shapes, modular platforms that allow for better airflow management, and AI-assisted design tools that can optimize shapes far beyond human intuition. Furthermore, as autonomous vehicles become mainstream, the absence of traditional driver interfaces may allow for entirely new exterior forms tailored for maximum aerodynamic efficiency.

Collaboration between designers, engineers, and data scientists will become even more crucial as automotive design continues to adapt to changing mobility needs. Ultimately, innovation in design will remain a powerful lever for achieving sustainability goals and enhancing vehicle performance.

Conclusion: Why Automotive Design Matters More Than Ever

Automotive design is not just about crafting attractive vehicles—it’s a science-driven discipline that plays a critical role in shaping performance, safety, and environmental impact. From the subtle curve of a side mirror to the overall silhouette of the car, every design decision affects how a vehicle interacts with the air around it.

By focusing on aerodynamic efficiency and embracing new technologies, automotive design is helping to usher in a new era of cleaner, more efficient transportation. As we move forward into a world of electric and autonomous vehicles, the integration of aesthetic and functional design will become even more pivotal. In the race for efficiency and innovation, automotive design is leading the way.